CONTACT

E-mail: info@vst-display.com

TEL: 0086-13360078105

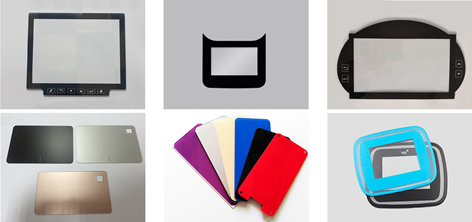

Glass cover is widely used in display field to play key roles of protection and decoration. Comparing to other material cover lens like PC/PMMA, glass cover has obvious advantages:

Good shock resistance and anti-scratch feature.

High temperature resistance and good resistance to flame retardant.

Good insulation characteristic and anti-corrosion.

Better transmittance with better optical performance.

Long service lifetime.

And here we would briefly introduce our glass cover lens solution from some aspects.

1. Material Type

Material Type

Thickness Availability

(mm)

Soda-Lime Glass

0.55~5.0

Aluminosilicate Glass

0.7~3.0

AGC Dragontrail DT-HW

0.7~2.0

Corning Gorilla Glass 2320

0.4~2.0

SCHOTT Glass

0.9~5.0

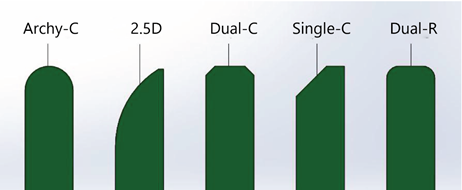

2. CNC Process Ability

High accuracy of 0.03 mm;

Abnormity cutting;

The thickness of cutting can be 0.1~5mm.

CNC precision machining forming, it can provide a variety of chamfering, holes, special-shaped and other customized processing.

3. Cleaning

Using USC(ultrasonic cleaning) to remove grease, dirt and Chemical residue from the glass surface. Keep the cleanliness high.

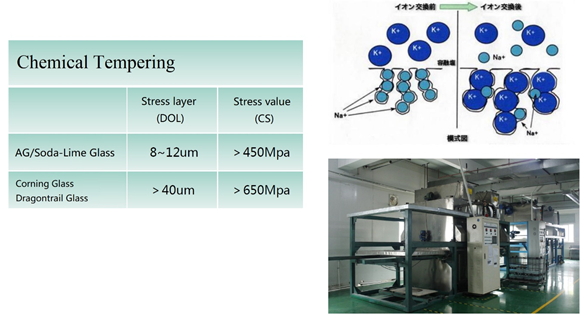

4. Chemical Tempering

Chemical tempering is to place the glass in the molten alkali salt, so that the ions in the surface of the glass exchange with the ions in the molten salt; Due to the volume change after the ions exchange, the two surfaces of the glass forms compressive stress which leads to internal tensile stress, thus achieve the effect of improving the strength of the glass.

With high strength, good thermal stability, surface deformation, chemical tempering can do appropriate cutting treatment without self-explosion phenomenon.

Normally chemical strengthening is used when the cover glass thickness lower than 3.0mm.

4. Physical

strengthening

Physical toughened glass is called quenched toughened glass.

The ordinary plate glass in the heating furnace is heated to close to the softening temperature of glass (600℃), through its own deformation to eliminate the internal stress, and then get the glass out of the heating furnace .Afterwards, high pressure cold air from multi-head nozzle is blown to the two sides of the glass, and the glass would be cooled to room temperature quickly and evenly, now physically strengthened glass is formed.

The physically strengthened glass would be in the internal tension and external pressure stress state, any partial damage will occur stress release and whole glass breaks into countless small pieces for which the debris is obtuse Angle, safe and harmless. The number of debris particles is larger than 100pcs in the area of 50*50mm

Normally Physical strengthening is used when the cover glass thickness larger than 3.0mm.

5. Printing Process

Fully automatic printing machine can provide multiple colors, multiple layers, high precision printing

High temperature ink(Ceramic ink)

IR ink

Metal ink

Anti-UV ink

6. Surface Treatment

AG Process: Etching;

AR Process: Evaporating;

AF Process: Spraying;

AG+AR

AG+AF

AG+AR+AF

AR+AF

DLC Coating

CONTACT

E-mail: info@vst-display.com

TEL: 0086-13360078105